Dartmouth's Energy Future

Awards: The Dartmouth Society of Engineers Prize for Best Engineering Capstone Project.

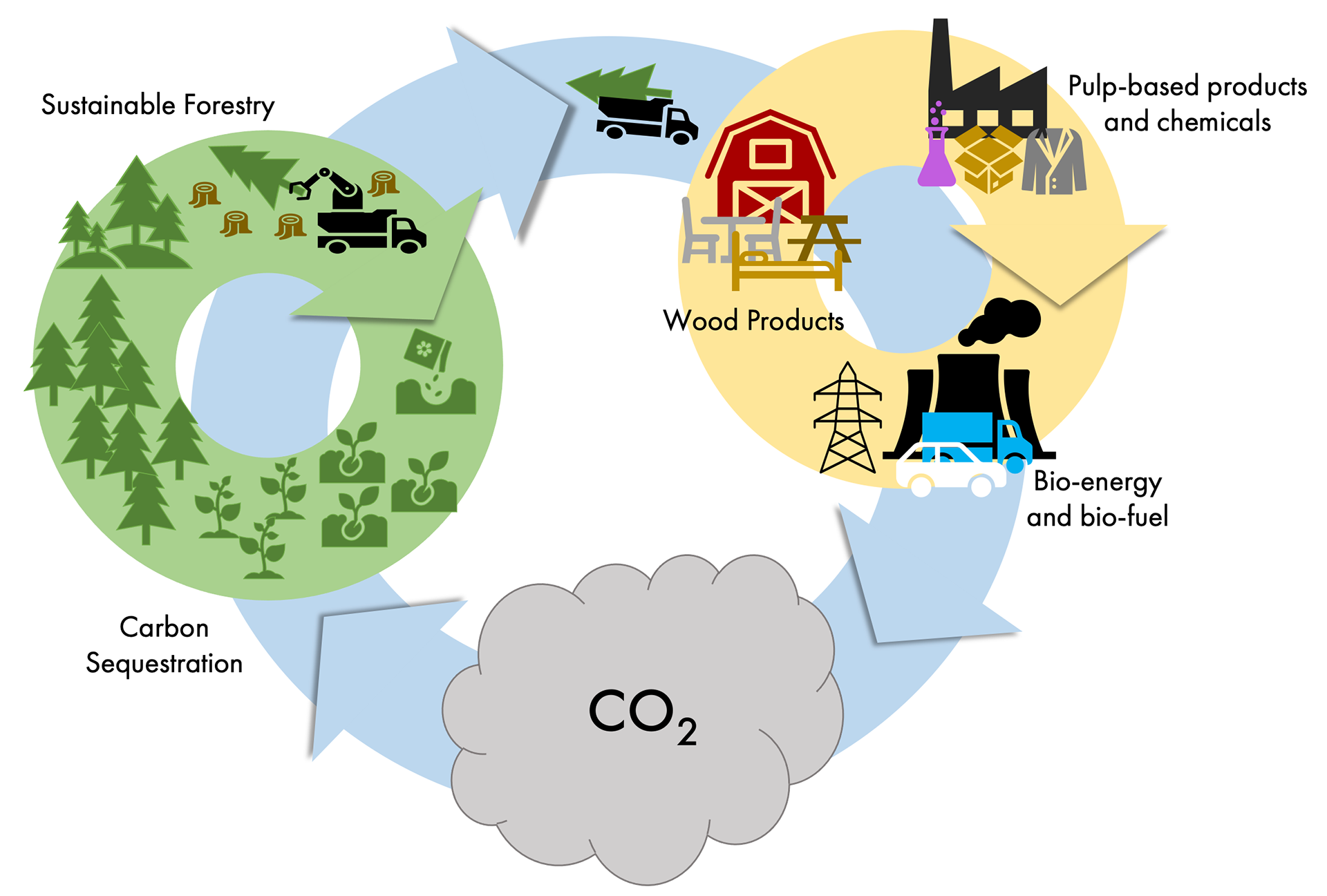

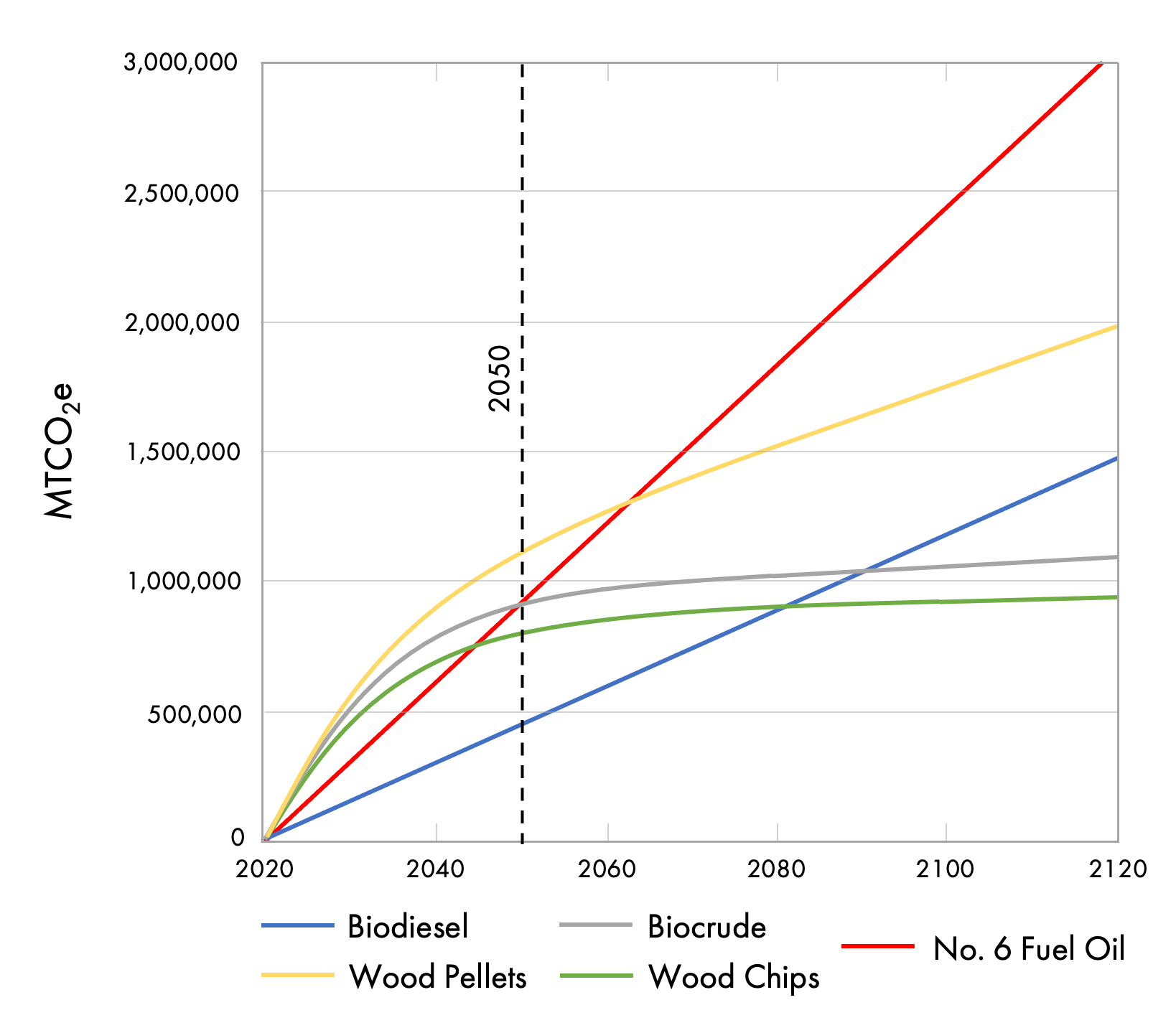

In January 2019, Dartmouth College announced plans to build a biomass heating plant, burning locally sourced forest residue to meet its carbon emission goals (50% reduction in emissions by 2025 and 80% reduction by 2050 from 2010 baseline). However, while biomass does not introduce new carbon into the atmosphere, biogenic fuels are less energy dense than their fossil-fuel counterparts and actually emit more carbon at the moment of combustion.

As promising as the biomass plant may appear on paper, with less than a decade left to limit global warming to 1.5°C, natural sequestration for biogenic fuels will not offset emissions on a time scale that is relevant for addressing climate change.

Biogenic carbon takes time.

Dartmouth needs a new framework.

My team was tasked with developing pathways for an alternative heating system to direct Dartmouth's $80-million campus energy investment. After establishing the incompatibility of biomass heating, we interviewed industry exports and compiled case studies on new technologies such as agriculture-derived biofuels, hydrogen fuel cells, building energy retrofits, heat pumps, and more.

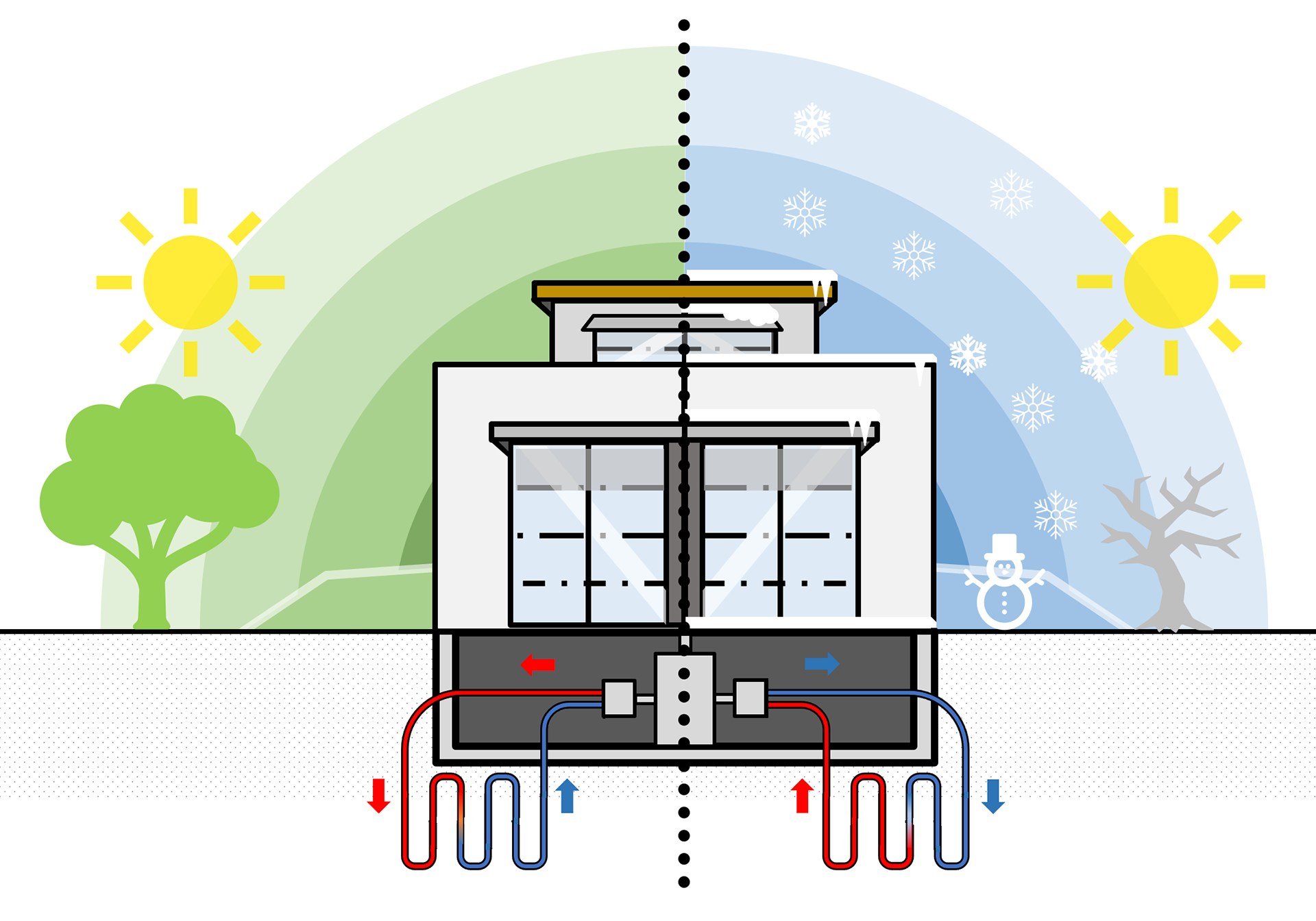

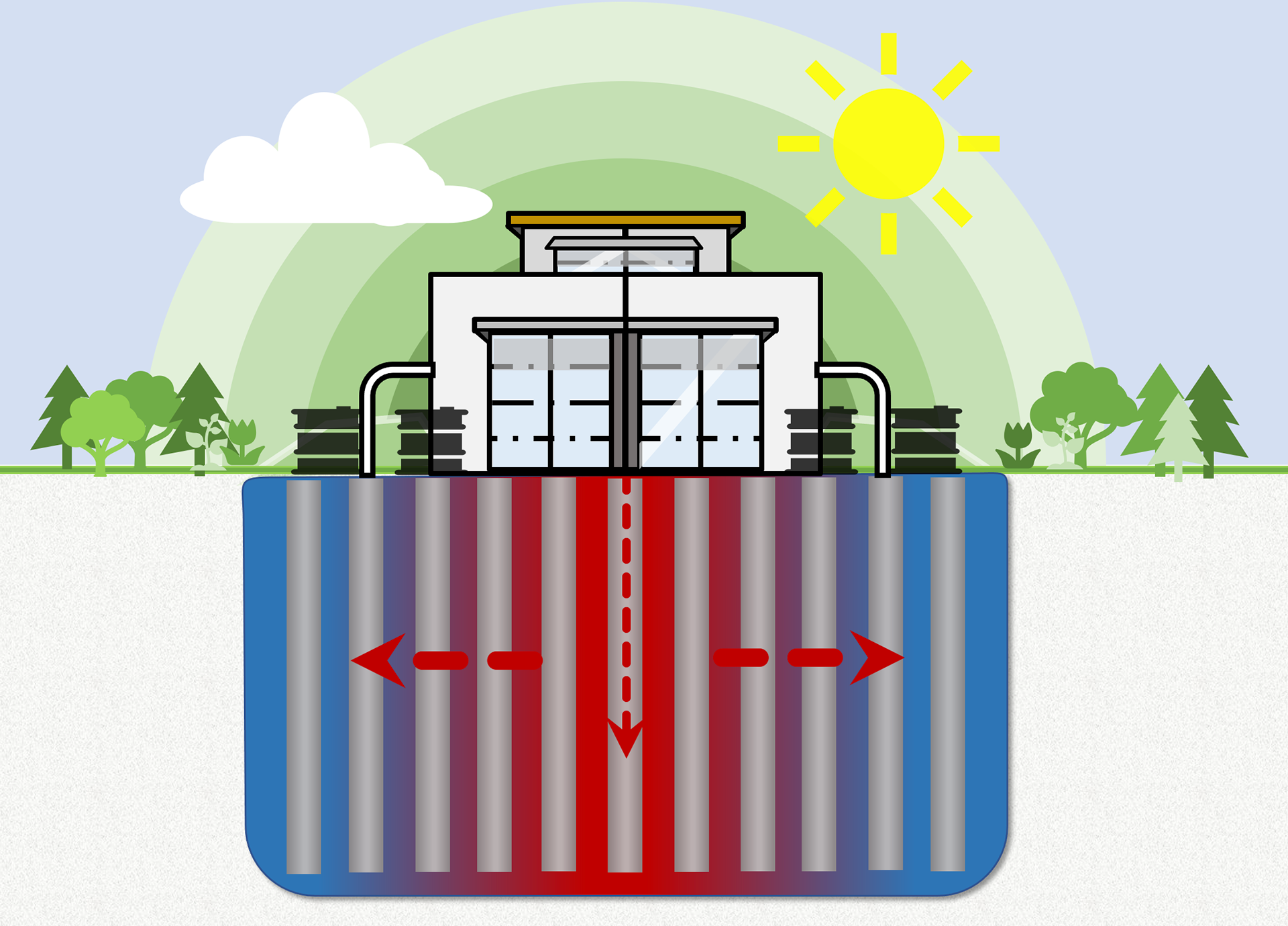

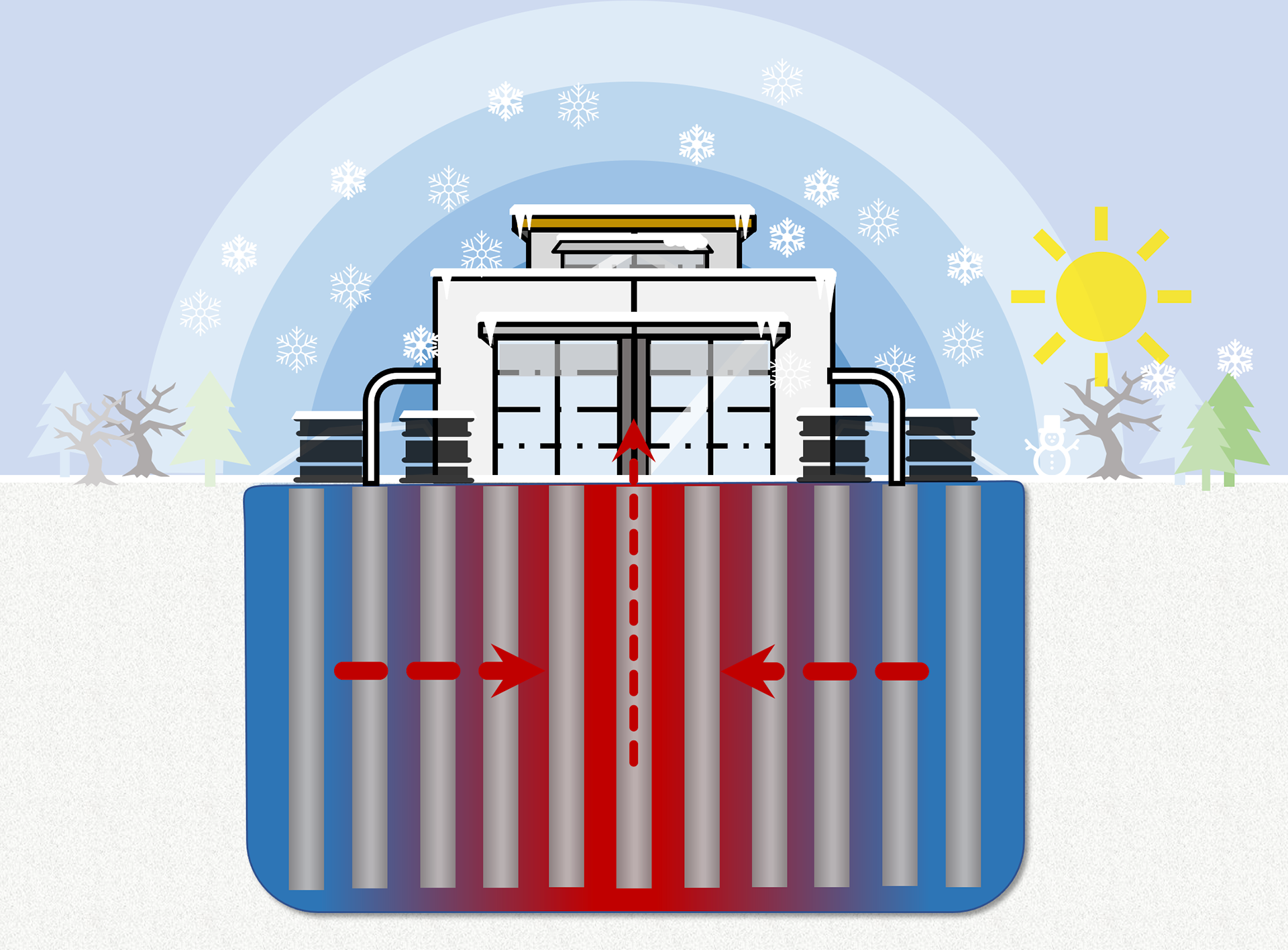

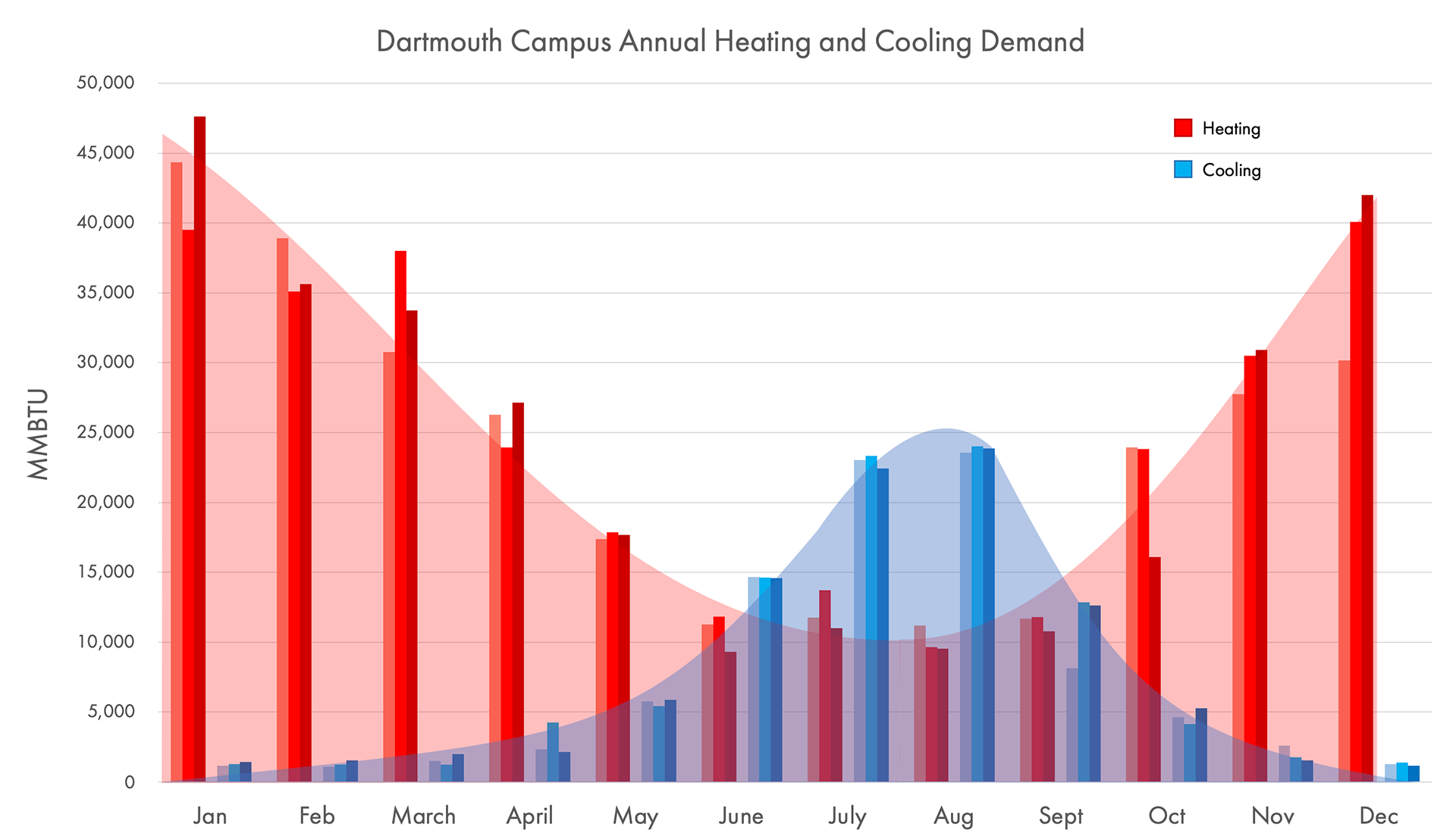

I researched ground-source heat pumps (GSHPs) which use the steady temperature of the earth to provide seasonal heating and cooling. The analysis included creating models that tracked seasonal changes in the system's coefficient-of-performance and mitigating Dartmouth's regional heating-degree-day imbalance. To offset the Northeast's greater heat extraction during the winter, heat-recovery chillers (HRCs) and solar-thermal arrays can be used to supplement the GSHPs and reject additional heat into the ground. Essentially the GSHP boreholes act like a battery, storing thermal energy.The diagrams below show the seasonal heating and cooling difference and borehole thermal storage mechanism.

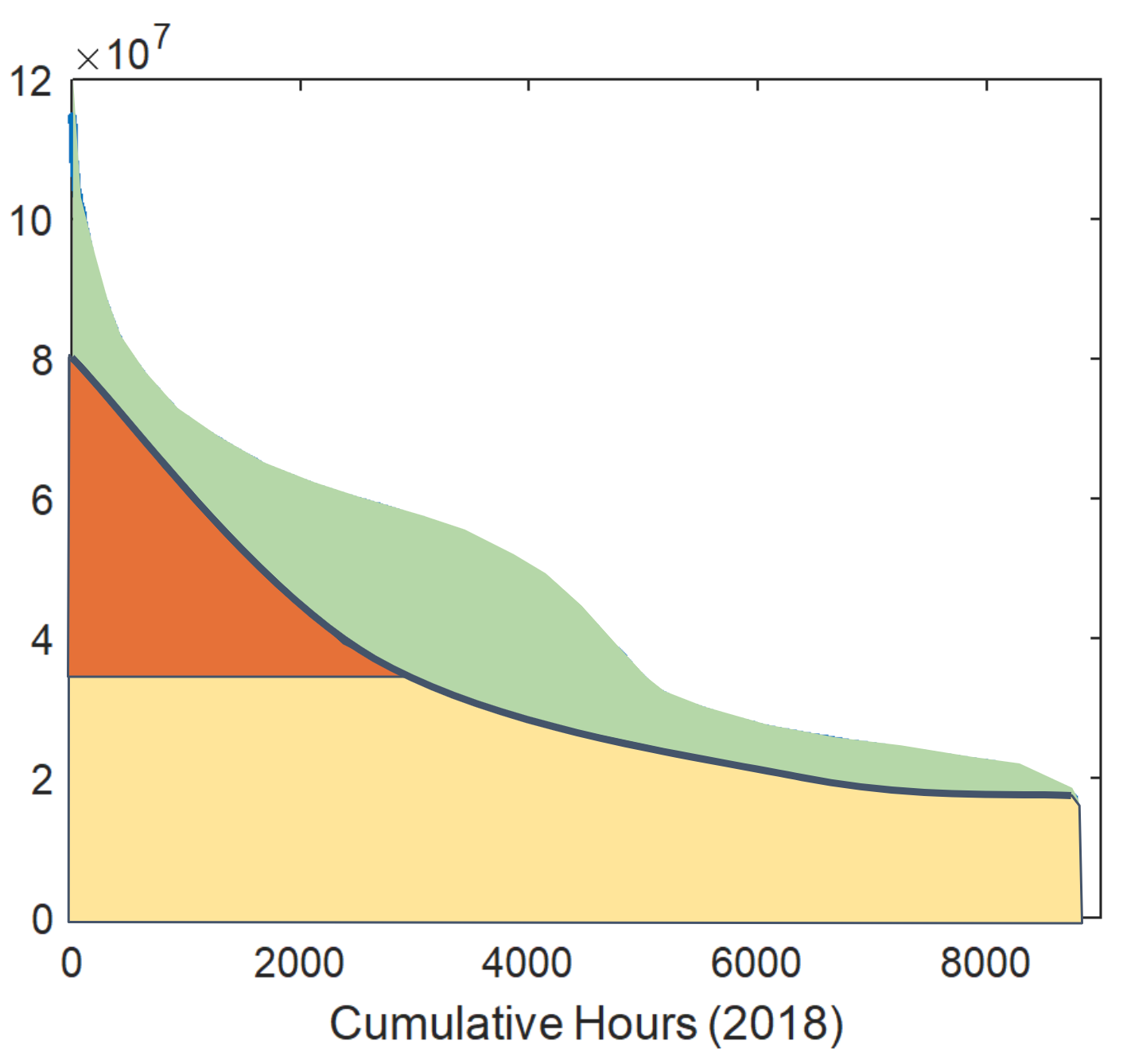

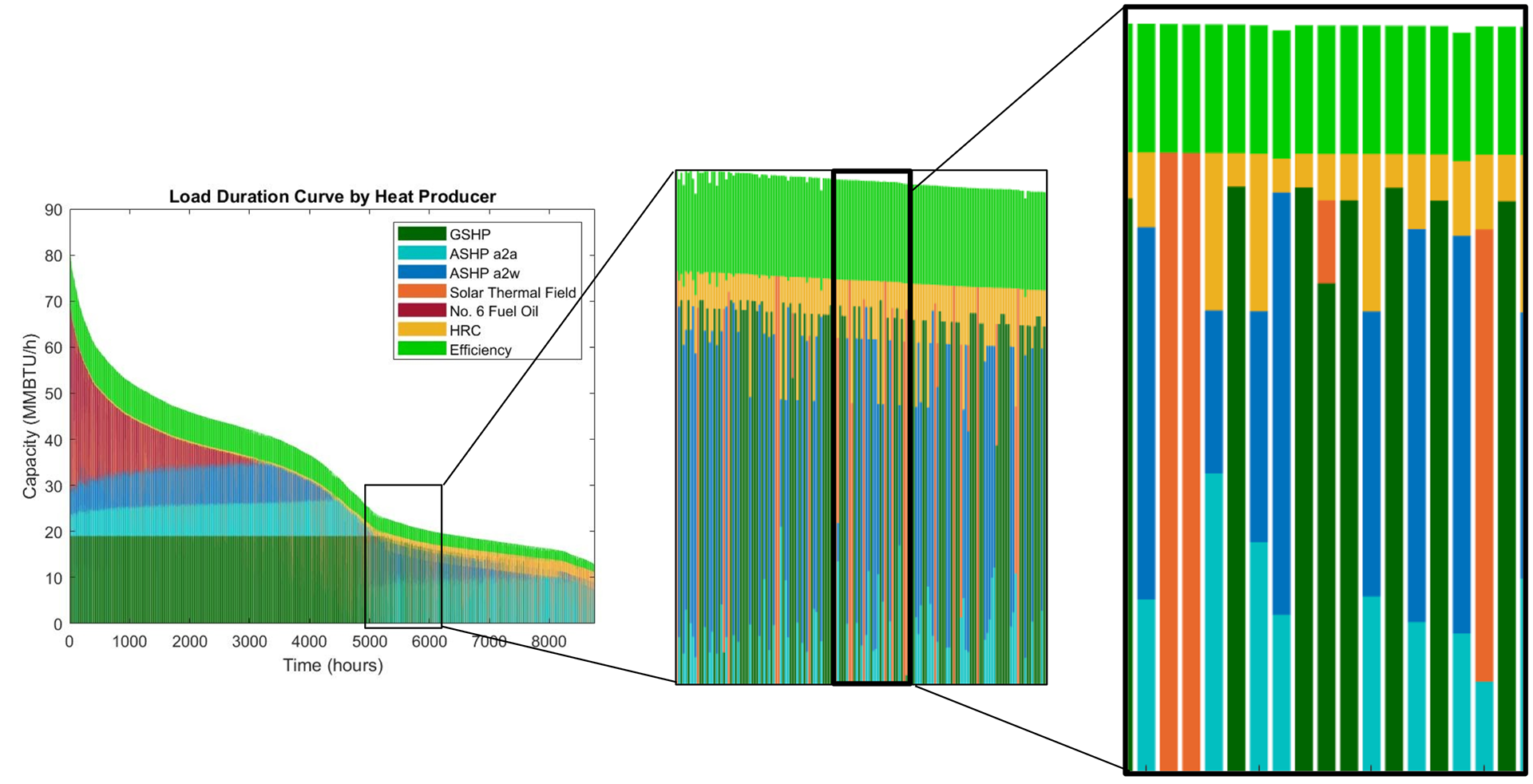

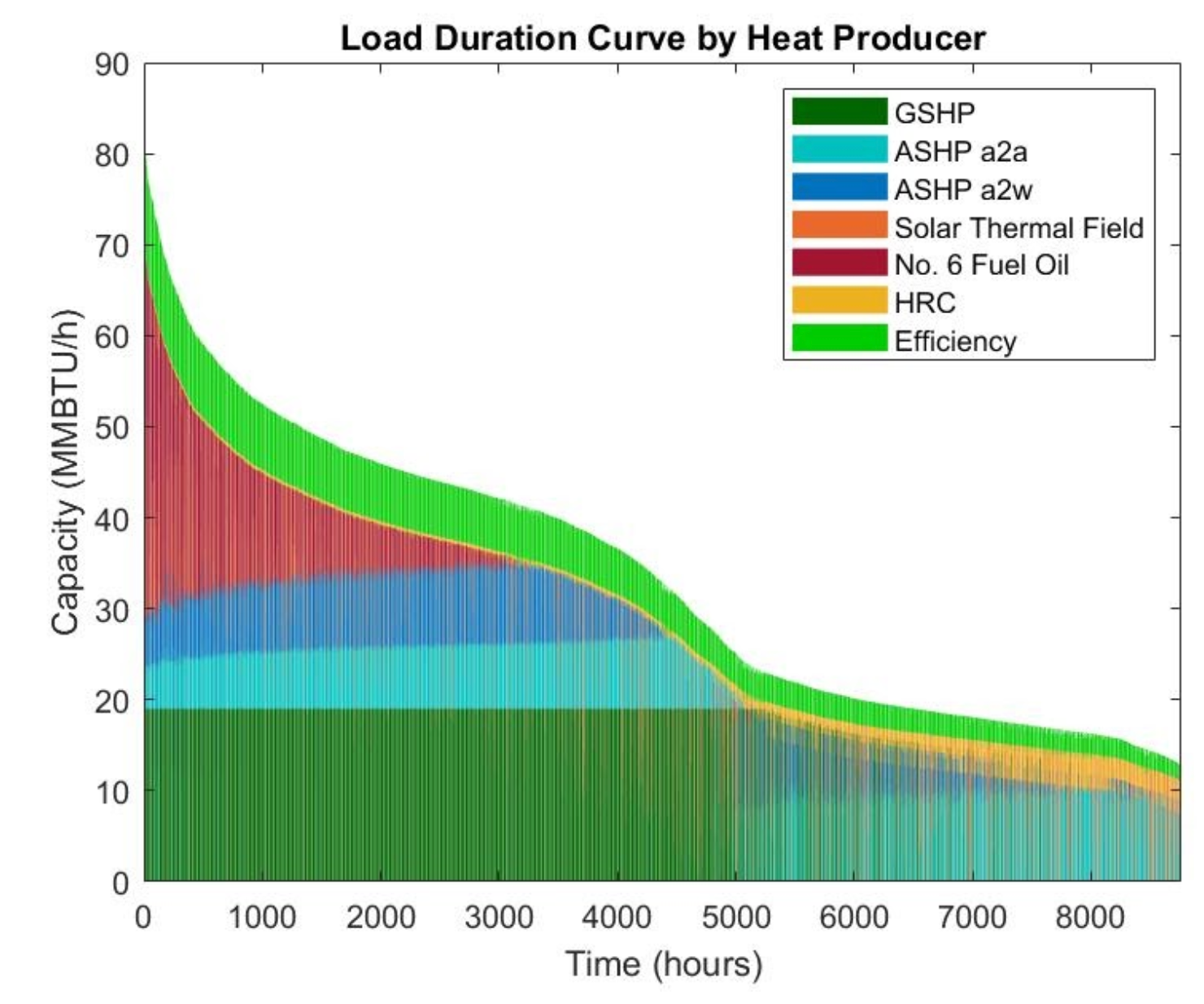

The heating and cooling demand graph depicts Dartmouth's seasonal heating imbalance (bottom left) while the load duration curve illustrates the campus heating demand at every hour of the year (bottom right), which is currently met by burning no. 6 fuel oil. Our framework refills the load curve with low-carbon technologies; reducing total demand through building efficiency retrofits, meeting base load with non-combustion technologies, and saving combustion for peak heating. Data for this project was derived from normalizing existing heating plant energy meters and verified through meetings with Dartmouth's Facilities and Operations engineering team.

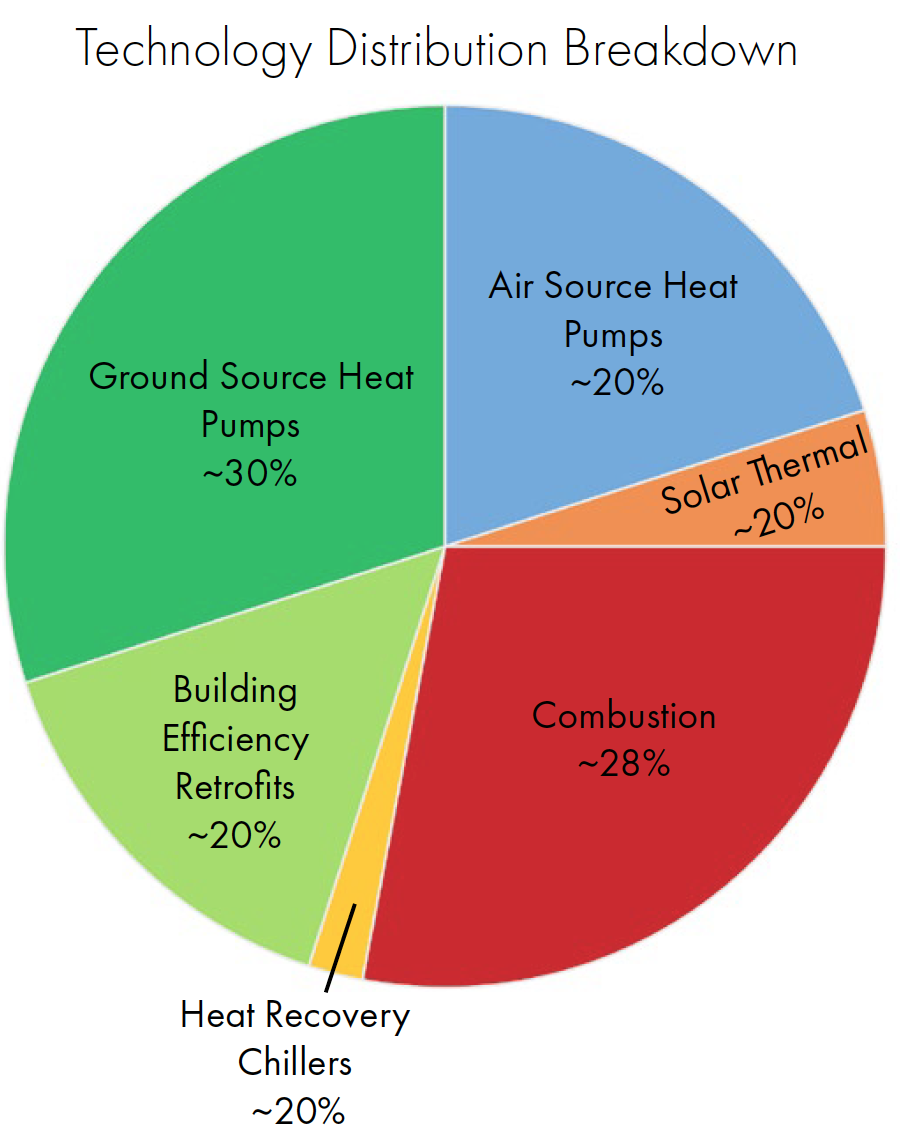

The data from GSHPs and other alternative technologies research (Building Efficiency, Solar Thermal, Air Source Heat Pumps, Biomass, Biocrude, Biodiesel), were normalized to their emissions per unit of heat output, as well as their levelized cost of energies (LCOE) which is the total capital and operational cost over the lifetime of heat generation.

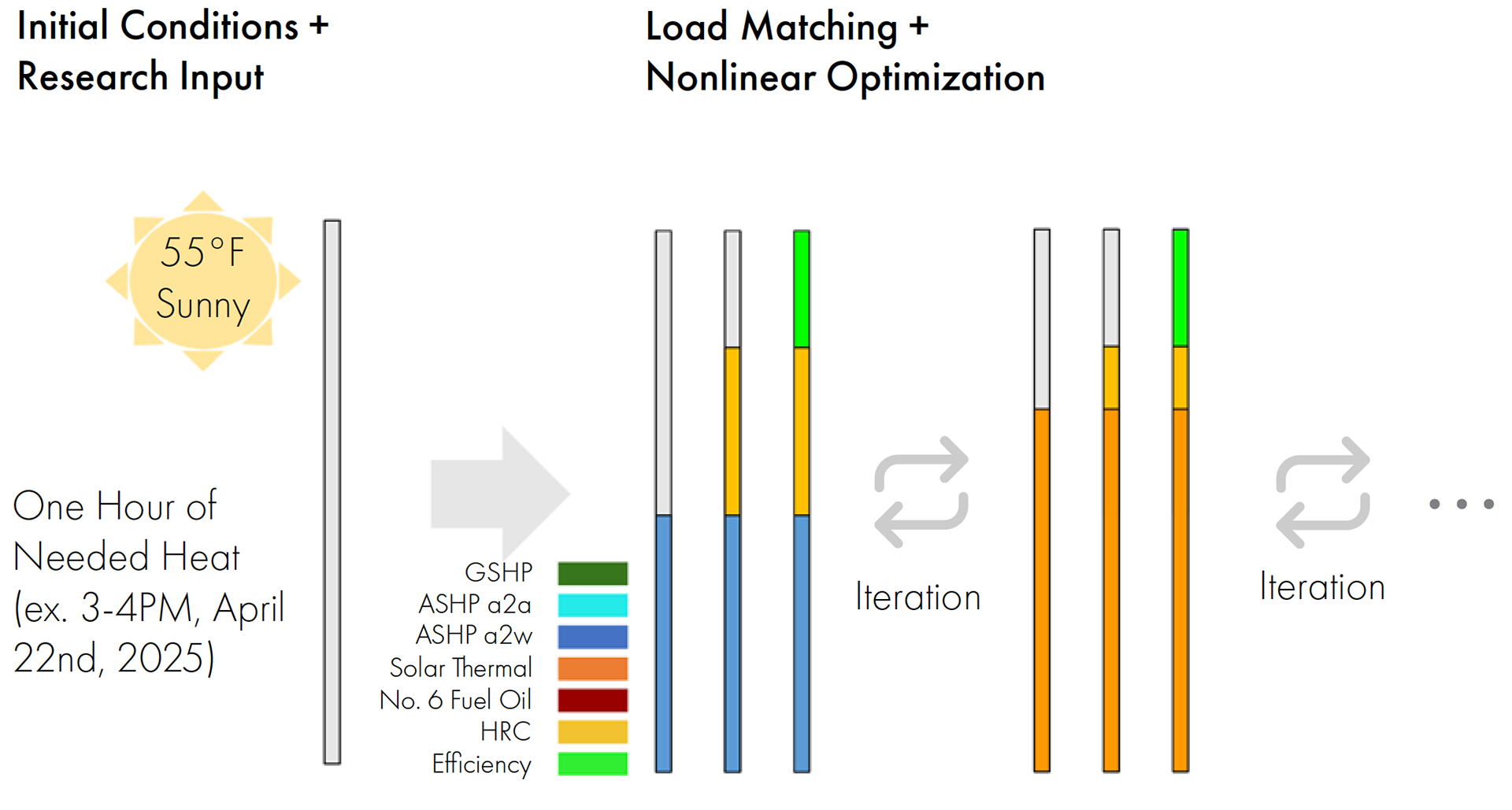

Our team built a non-linear Matlab optimization model to calculate optimal distributions that minimize cost and emissions while meeting Dartmouth's annual energy demand. This included initial conditions such as hourly heating changes, seasonal solar irradiance, and other key factors.

The objective function in $/year, used a weighted sum of capital, operational (electric), and carbon costs. Each iteration of the function tests different combinations of technologies to find the optimal distribution of technologies. The final recommendation calculates carbon emissions of 9,450 metric tons, which meets Dartmouth’s 2025 and 2050 emission goals. It also meets the requirements for a 15-year net present cost (NPC) that is lower than business as usual, and this NPC also improves even further when considering longer time horizons.

The geothermal facility (far right) has HRC technology integrated with GSHPs and also includes a bore field and solar thermal array. This supplies the chilled water loop (blue loop) in the summer as well as baseline heating in the winter. Since the geothermal facility is not sized for peak heating, it will act as a preheat for the new low-temperature hot water (LTHW) distribution system (red loop). Building efficiency measures and air-source heat pumps will be installed on a per-building basis. The heating plant (far left) would burn no. 6 fuel oil (or any other alternative) to heat the incoming hot water return loop, before redistributing it to campus. Currently the heating plant produces steam for electricity co-generation (yellow loop), and this will eventually be replaced with purchased electricity as combustion demand decreases and the old steam distribution system is removed.

This project was presented to the Executive Vice President (Rick Mills), VP of Operations (Joshua Keniston), and Provost (Joseph Helble) of Dartmouth. As of 2022, the LTHW distribution system has been installed on campus. Upon my 5 year reunion in 2025, I caught up with Rosie Kerr: Dartmouth's Director of Sustainability. She told me that campus upgrades are in motion and that our work has had a lasting impact on the college.

Team: Mallory Byrd, Mary Tobin, Alexander Derenchuk, James Gibson, Quinn Cooney, Kayleigh Abbott, Camilo Toruno, and Kevin Yang