Investigations of Mycelium

Dartmouth Engineering, Senior Thesis

High Honors Distinction

Buildings and their related construction are responsible for approximately 39% of global energy-related carbon emissions, 28% of which are embodied carbon from processes such as manufacturing and transportation. For my senior honors thesis, I researched how mycelium could be applied as a novel building material to decarbonize the built environment, performing mechanical and thermal properties tests to determine its suitability as a thermal or load-bearing material.

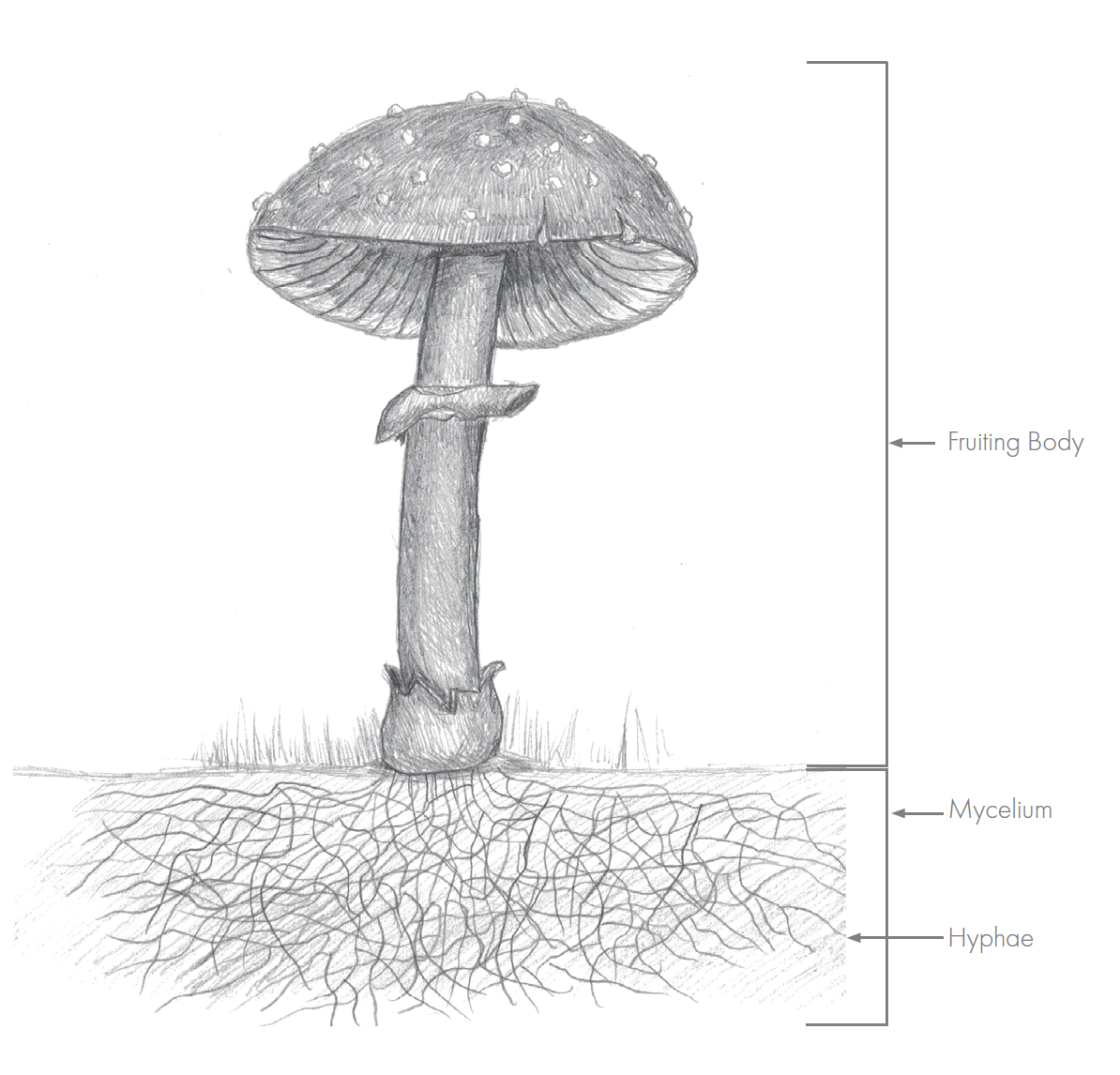

Mycelium is the fungal body of the mushroom. As a decomposer, fungi organically decompose agricultural waste products and can sequester both carbon and waste as they grow. In the future, this bio-based material could be grown on construction sites to fill different cavities and further reducing emissions associated with material transport and VOC emissions.

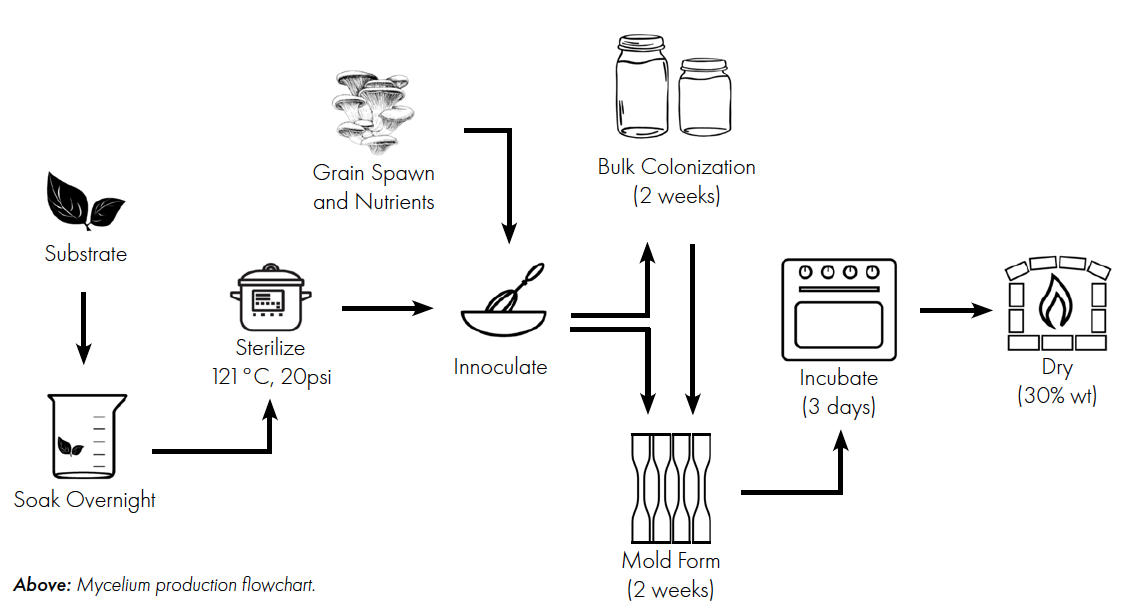

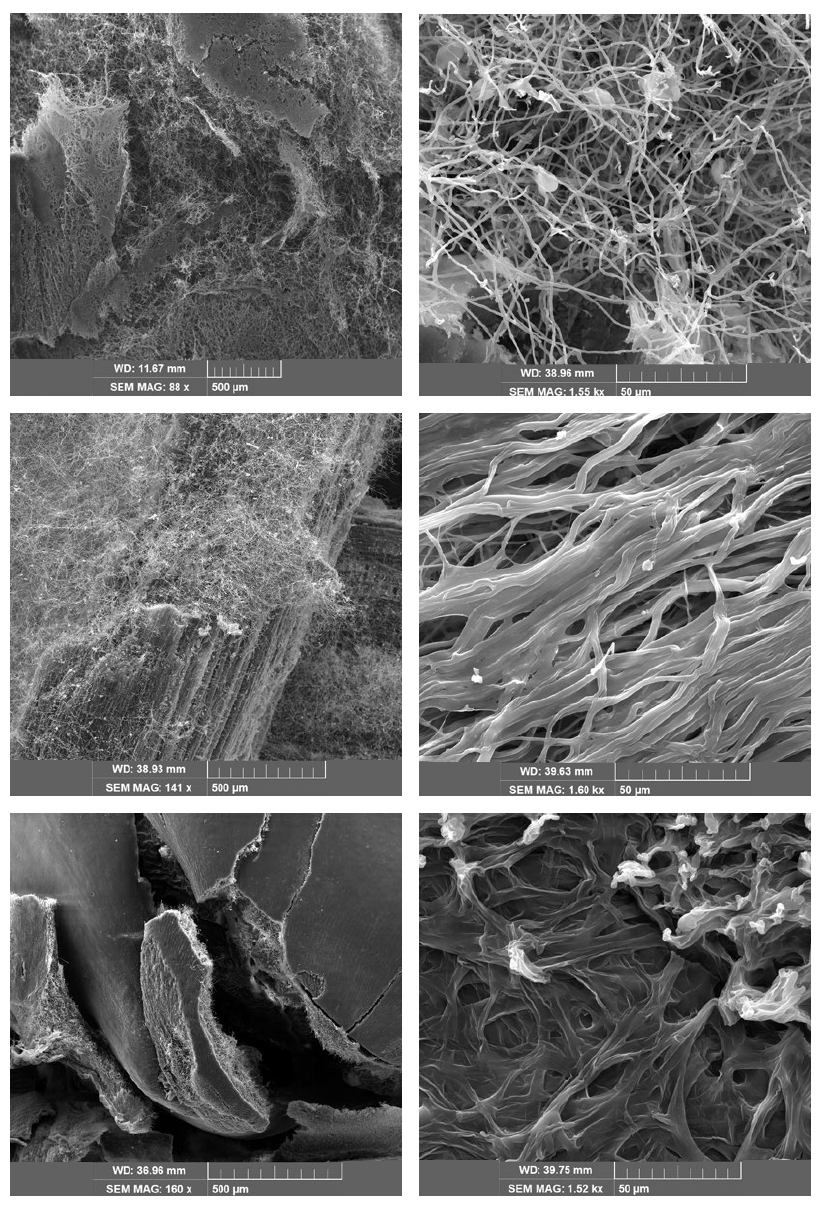

After reviewing existing literature on the topic, I developed a novel production workflow that standardized and streamlined mycelial growth. To determine the optimal fungal strain, I coated samples with gold dust and used scanning electron microscopy (SEM) imaging to characterize the growth density and thickness to determine which strain was best suited for thermal or mechanical building materials.

Scanning Electron Microscopy (SEM) images of several different mycelium strains. The growth density and thickness of the different strains informed whether the strain was suited for thermal or mechanical building materials. (From top to bottom: Oyster, Proprietary Ecovative, Reishi)

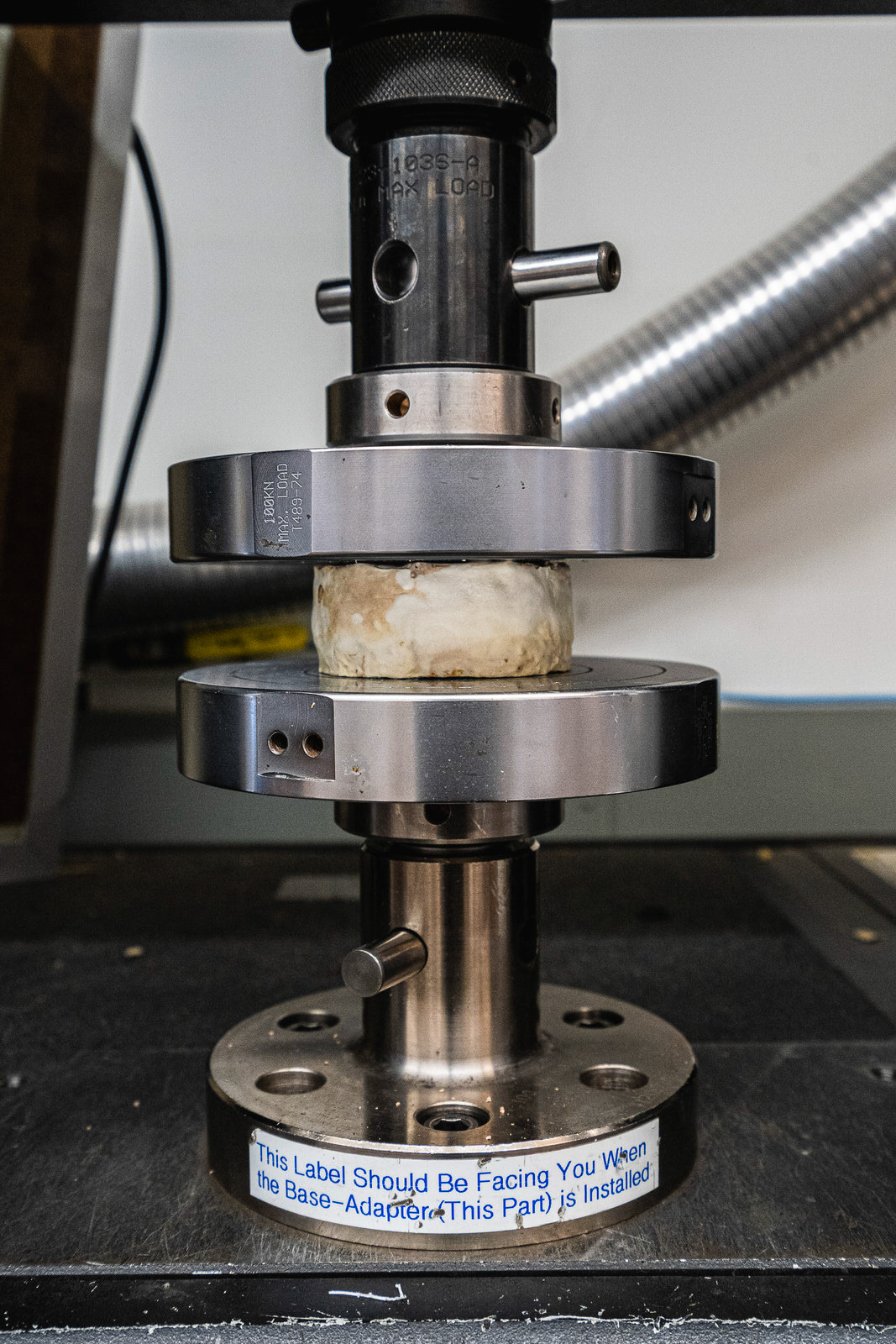

Compression and tensile tests showed typical stress-strain curve behavior under ASTM-D1621 for rigid cellular plastics. While the measured material strengths were within literature ranges, they were too low to be considered for mechanical building materials. Further testing of growth with cross lamination or processing should be pursued.

Insulation testing was based on ASTM-D5334 using a Tempos Thermal Analyser with modulated nutrient additions and growth period. Results indicated that the standard practice of full colonization may not yield the best thermal performance — something that had not been documented before in literature. When exposed to fire, conventional petroleum-based foam insulation tends to melt and burn, producing toxic fumes. In fire resistance tests, a flame was applied directly to the samples and the resulting char thickness was measured. All mycelium samples had less than 0.75 inch charring depth at 10 minutes, while the extruded polystyrene (XPS) sample melted through1 inch within 10 seconds.

Mycelium materials can also possibly sequester industrial waste. While conventionally grown on agricultural byproducts, they are able to grow to some degree on materials such as foamcore, PLA, and XPS. They can also incorporate silica as a fire retardant, opening up a pathway for upcycling glass waste. A test-wall of mycelium bricks and insulation was set to be built in a Tiny House as a part of Dartmouth's Structural Analysis course. However due to COVID-19 the project was postponed indefinitely. With its ability to be grown on-site, and also sequester carbon, agricultural byproducts, and industrial waste, mycelium may very well be the future of building.